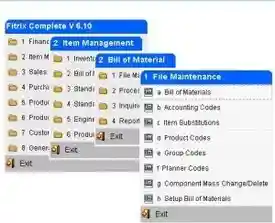

Bill of Materials

These bills of material are used by other modules within Fitrix to streamline business processes, provide effective planning tools, and to manufacture products in a consistent and timely manner.

- Production Order Processing – uses standard bills of material when creating production orders to manufacture products. The standard bill is copied to the production order bill as a starting point

- Material Planning – uses standard bills of material to plan strategic production and purchases, in support of a longer term production plan

Features/Function Highlights

Item Maintenance

- Global entry option

- Departmental entry option

- 80 character description

- User-Defined units of measure

- Multiple units of measure per item can be used for purchasing, and selling

- Multiple user-defined reference table entries

- Multiple user-defined fields

- Single-Level and cumulative lead-times

- Phantom items

- Inventory and non-inventory items

- Unit cost breakdown includes Material, Labor, Setup, Overhead, Outside Process

- Direct access to additional maintenance for Bill of Material, Standard Routing, Warehouse balances

- Unlimited notes for additional description

Bill of Material Maintenance

- User-defined component sequencing

- Multiple uses of same component with same parent

- Component links to standard routing

- Bill of material copy

- Component mass replace

- Component mass delete

- Bill of material delete

- Component effectivity dates

- Alternate components

- Parent component notes

User-Defined Reference Tables

- Product code

- Group code

- Commodity code

- Accounting code

- Planner code

EOQ Calculator

- Analyzes movement history to determine optimum order quantity

CMLT (Cumulative Material Lead Time) Calculator

- Analyzes indented bill of material, standard routings to determine overall time to buy/make

Inquiries

- Item availability

- Bill of material: Single level format, Indented format, Access to notes

- Component where-used: Single level, End item

Reports

- Item list

- Sales catalog - quick reference for pricing, description

- Bill of material: Single level format, Indented format

- Component where-used: Single level, End item

- Component Effectivity