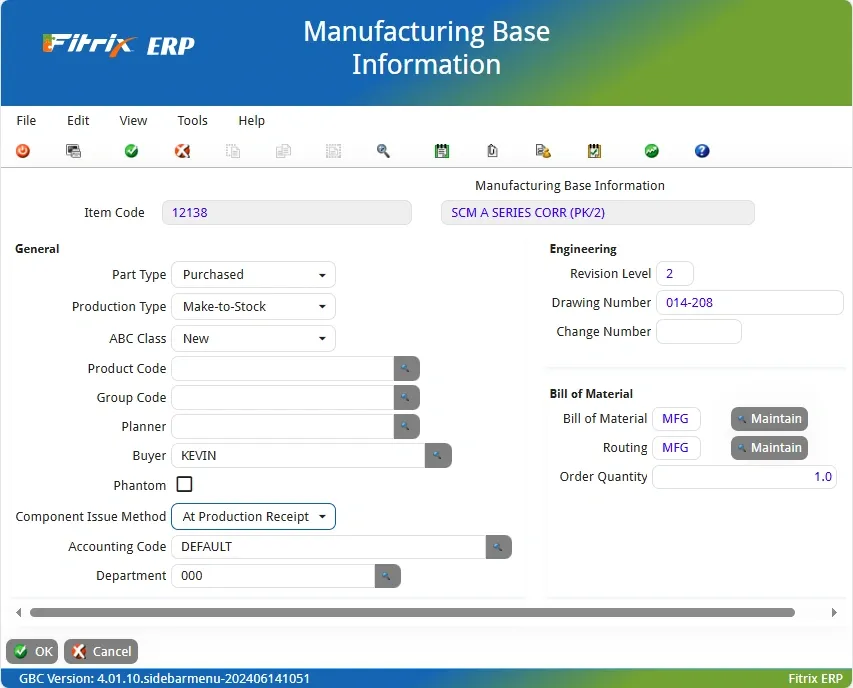

Make-to-Stock

In high or low volume environments, companies can plan and execute the production of standard products quickly and easily from standard bills of material.

Make-to-Order

The sales order for the make-to-order item automatically creates the work order needed to manufacture the item. The sales order screen references the work order number and vice versa. Purchase orders generated from the work order for any short components are also linked to both the sales order and work order.

Engineer-to-Order

In some cases each production run is a new product, consisting of purchased components, fabricated material, miscellaneous non-inventory items, and a variety of labor skills. Fitrix supports all of these material types, as well as multiple labor routing steps, each with its own rates for direct and overhead costs.

Job Shop

This environment requires all the elements of Engineer-to-Order as well as a very tight integration to the sales and purchasing processes. In Fitrix ERP purchase orders can be directly linked to the Production Orders requiring the material. The sales department can easily check the status of a job to communicate with the customer. Non-Inventory items can be used at the purchase, manufacture, and sales levels, where detailed descriptions of non-standard product are the rule rather than the exception.