Make-To-Order and Make-To-Stock Support

Fitrix gives you the flexibility to use a push system, a pull system or both, whichever makes the most sense for your business

With a make-to-stock or a push system you stock inventory and rely on past sales activity and forecasting to project demand. This ties up cash but reduces lead times to customers. With make-to-order or a pull system the reverse is true. Little to no inventory is stocked but customers may have to wait longer to get their order. In Fitrix ERP you are not limited to choosing one or the other and you can even mix it up; use make-to-order for some items or make-to-stock for others.

Customize the item to meet your customer's specifications

With Make-to-order it's much easier to customize an item using the Fitrix Product Configurator tool. Start from scratch and let the customer define all components or build your product to a certain BOM level (make-to-order) and then use the configurator to add the finishing touches.

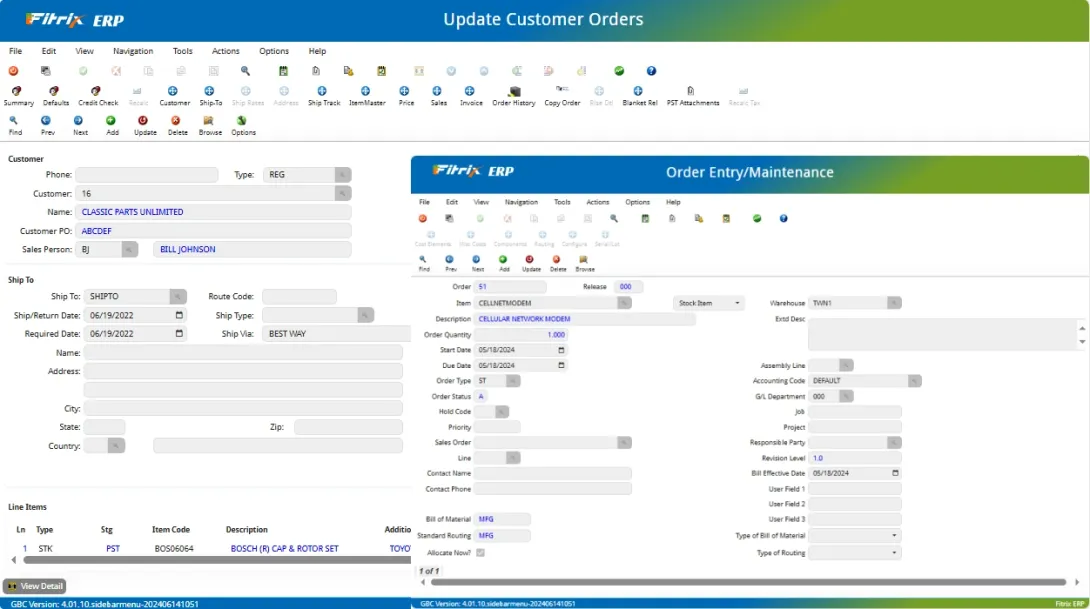

Strong link between sales order, work order and vendor purchase order for make-to-order items.

The sales order for the make-to-order item automatically creates the work order needed to manufacture the item. The sales order screen references the work order number and vice versa. Purchase orders generated from the work order for any short components are also linked to both the sales order and work order. When the PO is received warehouse personnel are notified as to what work order/sales order requires the components.