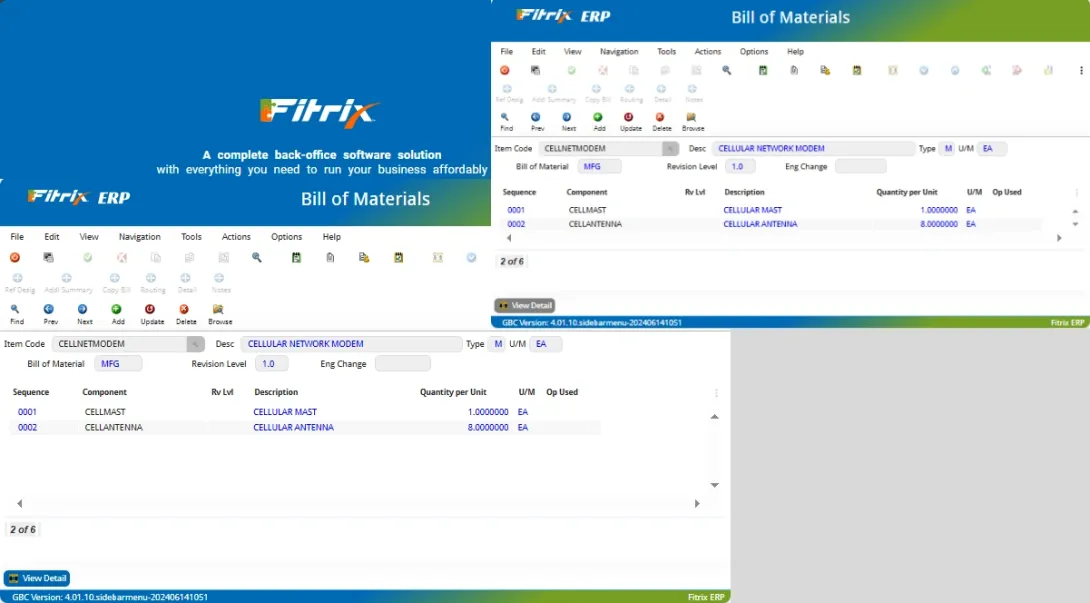

Multilevel bill of material gives a clear picture for both engineering and production

For the engineer it provides a snapshot of the complex structure of the product being designed. For the production employee it makes it easier to visualize how components come together to produce the end item.

Fitrix supports both "As Engineered" and "As Built" formats for the same manufactured item

Many manufacturers define multilevel bill of materials as "As Engineered" where the physical breakdown of a produced item is defined without regard to where the material comes from or how they are produced. You may also need to define an "As Built" format used in planning and production to define items being purchased and items being built as subassemblies.

More intuitive tracking of engineering changes

By having the ability to assign revision levels to your bill of material you can ensure the produced item is built according to the latest specifications. This tracking is also critical from a warranty service standpoint in that if the product is serviced after the sale, production history will reflect the revision level of the individual unit.

Better visibility of the details behind multiple usage of common components

Manufacturers may often use the same component part in more than one place for a manufactured item. Using a multilevel bill of material with reference designators shows exactly where it is being used. If a company is considering changing a component (i.e. - different model or supplier) a multilevel bill makes it easier to evaluate the potential impact of this change from both a cost and functionality standpoint.