When you’re looking to buy something for yourself or a loved one, there are three things to be considered: quality, price, and accessibility. This should be no different when it comes to purchasing materials for your company.

Having an Approved Vendors List (AVL) is an integral part to any ERP purchasing system. In some circles, this is also known as the ‘Approved Supplier List’ (ASL). This is a listing of vendors/suppliers that meets your company standards as far as quality, pricing, and delivery performance.

Many companies that use an AVL insist that orders only be placed with approved vendors, with the exception of a vendor being unable to deliver, and substituting another vendor requires manager approval.

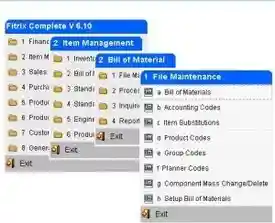

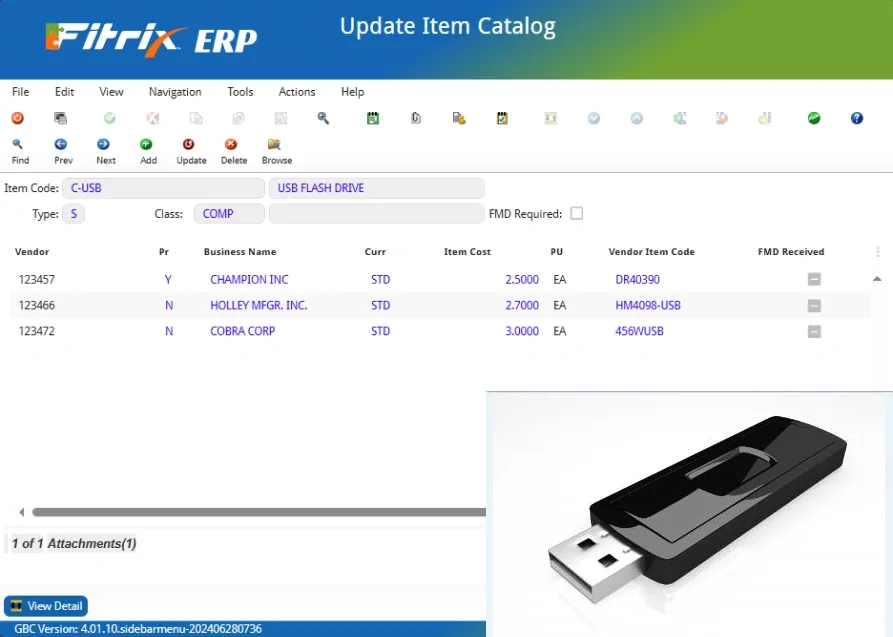

So how should the AVL work? First and foremost, you need to have the ability to associate vendors with the materials you buy from them. In Fitrix, we call these item/vendor catalogs.

The catalog allows you to store by item the vendors you buy it from, the cost, the unit of measure purchased in, the vendors part number, and if the item must be RoHS compliant, whether or not the vendor has submitted to you the item’s Full Materials Declaration (FMD).

Now that the software knows which vendors are approved for each item, there are several transactional points that make sure only these vendors are used. These include:

- Direct entry of vendor purchase orders

- Creation of purchase orders for backorders from sales orders

- Creation of purchase orders for short components on production work orders

- Assignment of vendors to internal purchase requisitions

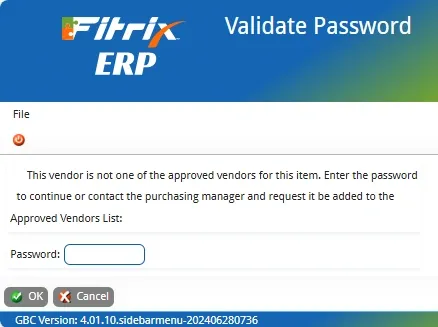

In Fitrix, when the AVL Required flag is set to Y and someone tries to enter a vendor that is not on the list, this message is displayed:

The employee can then enter the password if they know it, contact the Purchasing Manager to enter it for them for a one time buy, or request that the vendor be added to the AVL if they plan on buying from this vendor again in the future.

Just because a vendor is on the AVL doesn’t mean they should stay there indefinitely. Make sure you have the tools in place to keep your vendor list valid.

These include:

- Vendor Purchase Cost Analysis reporting to compare what you’ve paid each vendor for an item

- Quality control reporting that can give you by vendor by item their pass to fail ratio for items received and the reason for the failures

- Vendor Delivery Performance reporting that shows you percent on time versus late deliveries

Starting at the source with your vendors helps ensure your customers a high quality product, at a good price, when they need it.